Ball Valves

Ball valves are most often used where a meter control or shut is needed, including energy, chemical engineering, metalwork, and pipe fluid control industries. We offer an extensive array of ball valves to meet every customer need.

-

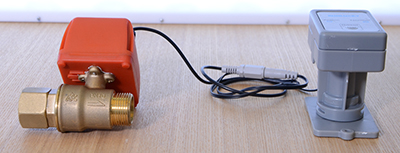

- Electric Ball Valves Electric ball valves are used to open and shut flow passages through a rotating output drive. Compared to other valve types, electric ball valves are able to withstand a higher meter, high pressure, and higher temperatures. They are also compatible with a wide array of media, including water, air, oil, acid, and alkali corrosive mediums...

- READ MORE

-

- Manual Ball valve RUNXIN offers an extensive array of manual ball valves, each of which is equipped with standard locking handles. To better meet customer needs, we also offer oval handles, tandem links, and spring return handles. Valve body materials include stainless steel and PPO. Please do not hesitate to contact us, and share...

- READ MORE

-

- Pneumatic Ball Valve Reversing the pulse electronic reversing valve to control the hydraulic actuator to drive the ball valve switch; After receiving the positive pulse signal, the electronic reversing valve changes the inlet and outlet directions of both sides of the hydraulic actuator to drive the ball valve to open; after receiving the negative ...

- READ MORE

-

- Intelligent Irrigation Ball Valve The residential timing intelligent irrigation valve simplifies watering by adjusting schedules based on soil moisture. Thanks to its LCD screen and IoT integration, you can control irrigation remotely, ensuring efficiency and saving water. This smart valve is ideal for municipal landscaping, agriculture, and home gardens...

- READ MORE

-

Small torque

The patented design structure (patent number: ZL201320732225.7) reduces the pressure placed on the balls by the valves.

The balls and the valve seat are made using high hardness and high-quality ceramics, making it easy to open and close the valves.

The ceramics themselves ensure there is no torque change even after long term usage due to the wear and abrasion resistance.

The torque on these ball valves accounts for only ¼ to 1/6 that of a metal seated ball valve, while the torque of those below DN50 account for only half.

-

Wear resistance

Ceramic features a high hardness, ensuring it can withstand harsh conditions. -

Corrosion resistance

Ceramic balls maintain an excellent chemical stability as they will not react with most chemical mediators and maintain their properties even when exposed to esters, alcohol, and hydrocarbons. -

No leaking

Through precise grinding, the sphericity of the ceramic balls is 0.005mm.

- Nominal diameter: DN15-DN200; Nominal pressure (PN): PN10-PN25

- valve seat and ball materials: alumina 95, alumina 99, zirconia, and silicon carbide, etc.

- Valve body materials: UPVC, PPO, 304, 316, 316L

- Drive mode: manual, pneumatic and electric.

- Connection type: threaded connection, flanged connection, UPVC glue socket and hot melting connection

- Wiring type: 2 wires, 3 wires

- Optional functions: auto return after power on, signal feedback, adjustable flow rate, remote control, automatic switch time setting

1) Silicon carbide core ball valve used in the laundry dosing systems

Ordinary alumina ceramic will be damaged by the detergent because it is highly corrosive.

As a result, the silicon carbide ceramic core is used in the ball valve.

At present, there are very few manufacturers that can produce silicon carbide ball core in the world. Runxin's major breakthrough in the production of silicon carbide ball core has promoted the application of ceramics in ball valves to a higher level.

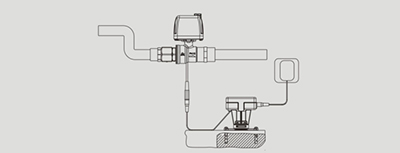

2) Ball valve applied in shut-off valve

Leakage sensors can be multi-connected, and once a leak is detected, the electronic ball valve is closed, potentially reducing water loss.

It can be repeated to use (replace the absorbent cotton)